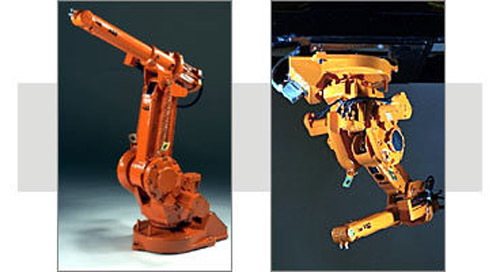

Arc Welding RobotsDuring the short time that industrial welding robots have been in use, the jointed arm or revolute type has become by far the most popular. For welding it has almost entirely replaced the other types except for the Cartesian, which is used for very large and very small robots. The reason for the popularity of the jointed arm type is that it allows the welding torch to be manipulated in almost the same fashion as a human being would manipulate it. The torch angle and travel angle can be changed to make good quality welds in all positions. Jointed arm robots also allow the arc to weld in areas that are difficult to reach. Even so, a robot cannot provide the same manipulative motion as a human being, although it can come extremely close. In addition, jointed arm robots are the most compact and provide the largest work envelope relative to their size.Usually arc welding robots have five or six free programmable arms or axes. |

|

| Off-the-shelf programmable robot arms are today available from different suppliers such as ABB, FANUC, PANASONIC, KUKA, MOTOMAN. |

|

Spot Welding RobotA robot can repeatedly move the welding gun to each weld location and position it perpendicular to the weld seam. It can also replay programmed welding schedules. A manual welding operator is less likely to perform as well because of the weight of the gun and monotony of the task. |

|

| Spot welding robots should have six ore more axes of motion and be capable of approaching points in the work envelope from any angle. This permits the robot to be flexible in positioning a welding gun to weld an assembly. Some movements that are awkward for an operator, such as positioning the welding gun upside down, are easily performed by a robot. |

|