Resistance spot welding (July 2000)

Description

Spot welding is one of a group of resistance welding processes that involve the joining of two or more metal parts together in a localised area by the application of heat and pressure. The heat is generated within the material being joined by the resistance to the passage of a high current through the metal parts, which are held under a pre-set pressure.

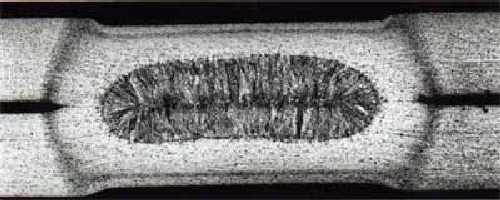

The process is used for joining sheet materials and uses shaped copper alloy electrodes to apply pressure and convey the electrical current through the workpieces. Heat is developed mainly at the interface between two sheets, eventually causing the material being welded to melt, forming a molten pool, the weld nugget. The molten pool is contained by the pressure applied by the electrode tip and the surrounding solid metal.

Click Enlarge

Fig.1. Resistance spot weld section

Current Status

Spot welding is one of the oldest welding processes. It can be used on very thin foils or thick sections but is rarely used above about 6mm thickness. It is used in a wide range of industries but notably for the assembly of sheet steel vehicle bodies where more than 100 million welds are made per day in Europe alone. High quality welds can also be made in stainless steels, nickel alloys, aluminium alloys and titanium for aerospace application.

Important Issues

The main areas of research are in materials, quality control and equipment.

- High strength steels, coated steels and aluminium alloys are of great interest to the automotive industry but can have weldability problems. Although the problems are understood, further improvements in weldability and electrode lives are still being sought. There are also limitations in the ability of spot welding to join sheet to tube, which need to be addressed.

- Weld quality is controlled mainly by good process control together with periodic testing of samples. While a number of monitors have been developed, there is still a desire to produce a low cost, reliable and robust in-process weld quality monitor, in order to reduce or eliminate periodic destructive tests. Ultrasonic non-destructive testing has been proved and widely applied at vehicle manufacturers but still requires skill and training to achieve high accuracy.

- Recent equipment developments have included improved controls, medium frequency power supplies, servo operated guns and automatic electrode dressing and changing tools.

Benefits

Spot welding offers a number of advantages over other techniques, including high speed, ease of automation and energy efficiency.

Risks

There are some limitations on material weldability but attention to correct setting up and good process control can solve most production problems. The main hazards are (i) the risk of crushing fingers or hands and (ii) burns or eye damage from splash metal. Little fume is produced but may need attention when welding coated steels or when oils or organic materials are present.

Copyright © 2002, TWI Ltd.

TWI information:

Information and advice from TWI are provided in good faith and based, where appropriate, on the best engineering knowledge available at the time and incorporated into TWI's website in accordance with TWI's ISO 9001 accredited quality system. No warranty expressed or implied is given regarding the results or effects of applying information or advice obtained from the website, nor is any responsibility accepted for any consequential loss or damage.

Click Here to Return to Paramount Stamping and Welding